API WCB Metal to metal seated ball valve

Floating/Trunnion mounted ball

Two-pieces body/Three-pieces body

Full/Reduced bore

Anti-static device

Blow-out proof stem

Fire safe design

Operation:Lever/Gear/Pneumatic/Hydraulic/Electric

| Available material | Body:A216-WCB,A352-LCB A351-CF8/CF8M/CF3/CF3M/Duplex Seat:ASTM A182-F6+STL/F304+STL/F316+STL/ F316L +STL Stem:A182-F6/F304/F316/F316L/F304L/17-4PH/F51 Ball:ASTM A182-F6+N/F304+N/F316+N/F304L/NF51+N |

| Standard | Design:API6D/API 608/BS 5351 Face to face:API 6D/ASME B16.10 End flange:ASME B16.5/ASME B16.47 BW end:ASME B16.25 Test:API 598 Fire safe test:API 607/API 6FA |

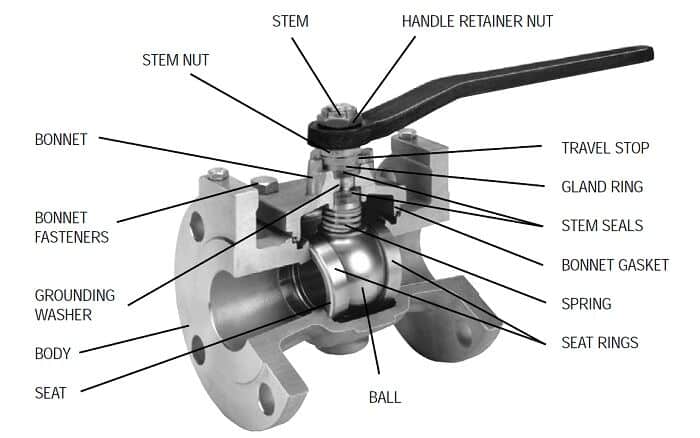

1.The valve body is cast with high quality materials and reasonable casting process. The ball is mounted on the side, and the middle flange and neck are connected by bolts.

2.Metal hard seal ball valve seat with spring/plate spring loaded metal seal structure, easy to open and close at high temperature, can be suitable for higher temperatures and a variety of medium conditions.

3.The low-mounted blow-out proof stem is adopted, and the inverted sealing structure is set to ensure the reliable sealing of the packing.

4.The internal pressure in the valve body cavity automatically release.

5.The connection plate can be matched with various driving devices. Includinghandle, gear, electric,pneumatic, hydraulic,pneumatic hydraulic,electro-hydraulic etc.

Metal seated ball valves are valves designed with metal to metal seal between the ball and the seats.The metal sealing ball valve produced by BESTOP solves the phenomenon of adhesive tape and high temperature stuck on the surface of the sealing pair,An elastic loading structure is used to ensure contact between the ball sealing surface and the seat seal under normal closure,Under high temperature conditions, it can effectively compensate the expansion of the inner parts and avoid the stuck resistance caused by high temperature, which is suitable for the use of small and medium caliber high temperature,The ball surface of metal hard seal ball valve adopts special surface hardening treatment, including supersonic spraying, nickel-based spray welding, carbide spray welding lamp, ball and seat surface hardness can reach HRC60 or above, up to HRC74.The sealing surface material can withstand temperature up to 540℃, the bonding strength of the material can reach more than 10,000 psi, with good friction resistance, impact resistance and other properties.Suitable for solid particles and abrasive media such as most of the harsh working conditions.It is suitable for petroleum, chemical, metallurgy, light industry, power station, urban construction water supply, low temperature conditions and oil, water, gas, natural gas and other long pipeline.