Carbon steel/stainless steel bellows seal globe valve

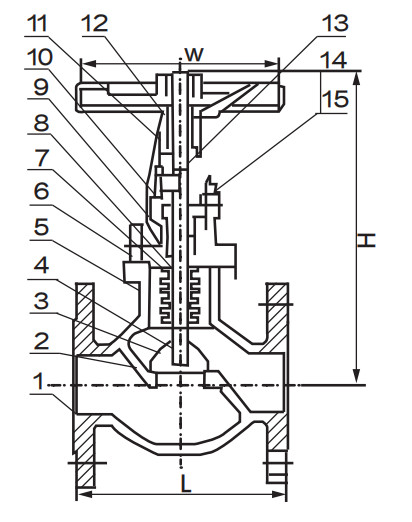

| No. | Part Name | Material |

| 1 | Body | ASTM A216-WCB, ASTM A217-WC1, WC6, WC9 C5, ASTM A351-CF8, CF8M, CF3, CF3M |

| 2 | Disc | ASTM A182-Gr F6a, ASTM A182-F22, ASTM A182-F304, F316, F321, F304L, F316L |

| 3 | Half Ring | ASTM A182-Gr F6a, ASTM A182-F22, ASTM A182-F304, F316, F321, F304L, F316L |

| 4 | Disc Cover | ASTM A182-Gr F6a, ASTM A182-F22, ASTM A182-F304, F316, F321, F304L, F316L |

| 5 | Stem | ASTM A182-Gr F6a, ASTM A182-F22, ASTM A182-F304, F316, F321, F304L, F316L |

| 6 | Gasket | Flexible+Graphite, Stainless Steel |

| 7 | Bonnet | ASTM A216-WCB, ASTM A217-WC1, WC6, WC9 C5, ASTM A351-CF8, CF8M, CF3, CF3M |

| 8 | Bellow | ASTM A182-F304, F316 F321, F304L, F316L |

| 9 | Packing | Flexible+Graphite |

| 10 | Packing Gland | ASTM A216-WCB, ASTM A217-WC1, WC6, WC9 C5, ASTM A351-CF8, CF8M, CF3, CF3M |

| 11 | Stem Nut | Copper Alloy |

| 12 | Handwheel | ASTM A536 Gr 60-40-18, A216-WCB |

| 13 | Locating Plate | 25, 45, 304, 316, 304L, 316L |

| 14 | Stud | ASTM A193-B7, A320-B8, A193-B8M |

| 15 | Hex Nut | ASTM A194-2H, A194-8, A194-8M |

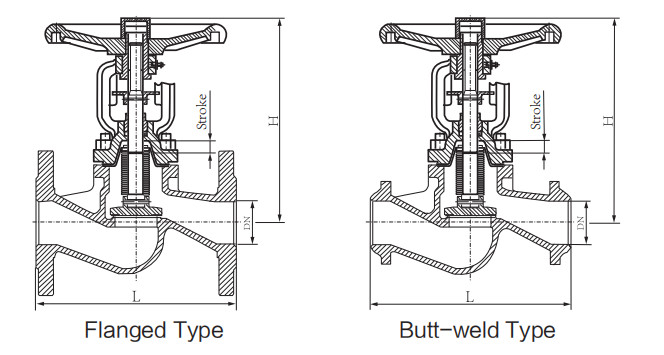

| Part Name | Material |

| Body | 1.0619(A216 WCB), 1.7357(A217 WC6), 1.4408 (A351 CF8M) |

| Seat | 13Cr, STL6 |

| Disc | 2Cr13+QT, A105, F316 |

| Bellows | SS304, SS316 |

| Stem | 2Cr13, F316 |

| Gasket | Graphite+Stainless Steel |

| Bonnet | 1.0619(A216 WCB), 1.7357(A217 WC6), 1.4408 (A351 CF8M) |

| Blot | A193 B7, A193 B16, A193 B8M |

| Nut | A194 2H, A194 4, A194 8M |

| Packing | Graphite |

| Gland | 1.0619(A216 WCB), 1.7357(A217 WC6), 1.4408 (A351 CF8M) |

| No rot. Device | A105, F304 |

| Stem Nut | GGG40.3, Cu Alloy |

| Grease Nipple | Cu Alloy |

| Handwheel | Steel |

| Lock Nut | C.S |

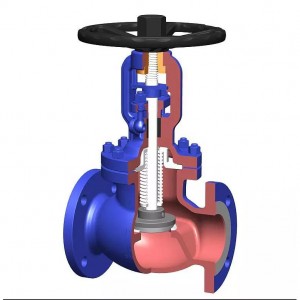

1.Bellow seal element.The key part of bellow sealed globe valves is metal bellow. It is the connection between cover and stem by automatic roll welding. The metal bellow can keep the stem part zero leakage.

2.Benefited from the cone and streamline shape design,the disc has reliable sealing performance and longer service life.

3.Double seal design(bellows+packing).Bellow and packing can protect from leakage and provide excellent sealing performance.

4.Grease nipple. It can directly Lubricate the stem, nut and sleeve.

5.Ergonomic hand wheel. It provide longer service life and easier operation.

1.OEM & customization capability

2.Our own foundry(Precision casting/Sand castings) to guarantee fast delivery and quality

3.MTC and Inspection report will be provided for each shipment

4.Rich operating experience for project orders

5.Certificates available:WRAS/ISO/CE/NSF/KS/TS/BV/SGS/TUV …