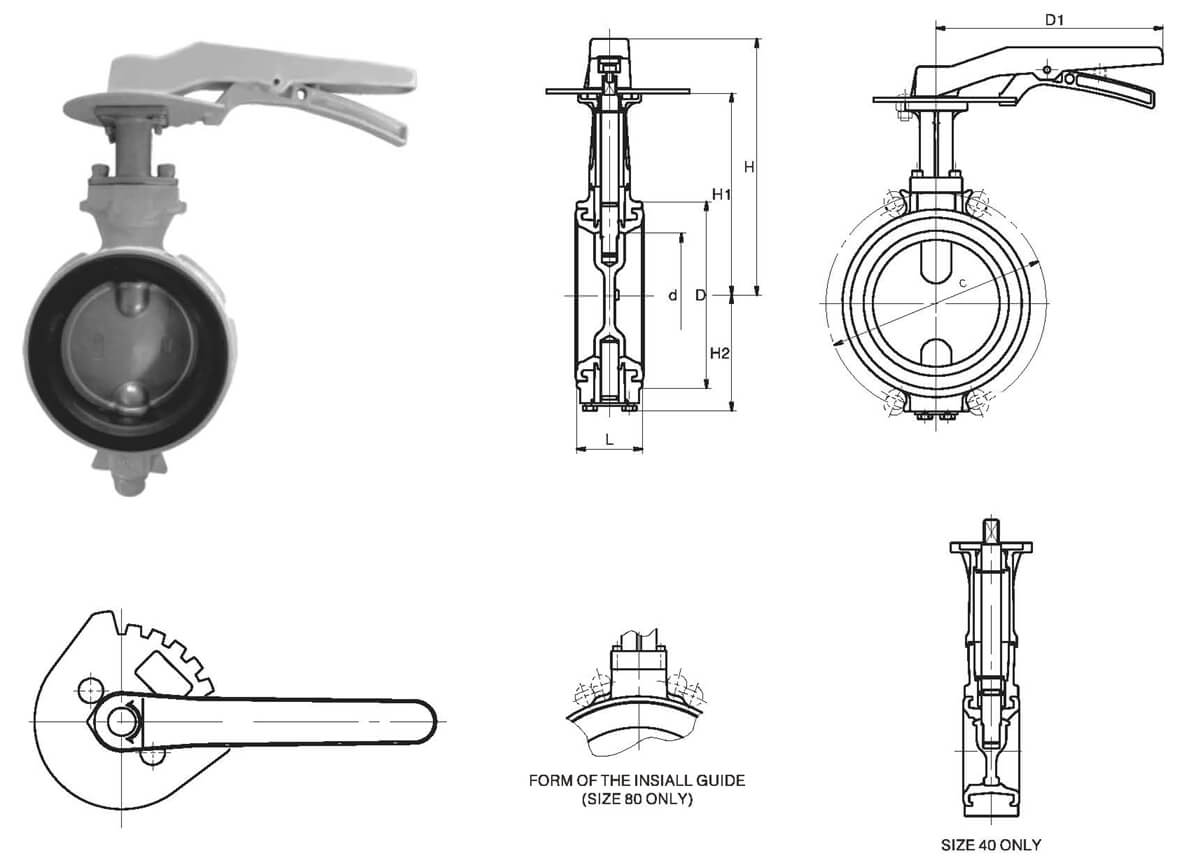

Center line anti-condensation butterfly valve

| Part Name | Texture of Material |

| Body | Die casting aluminum alloy |

| Plate | Stainless steel 304/316/316L |

| Seat | EPDM/NBR/Fluorine rubber |

| Stem | Stainless steel 416/304/316/316L |

1.Ultra light aluminum alloy valve torque is small, easy to use, to prevent corrosion.

2.Excellent durable sealing performance, anti condensation butterfly valve multi-level progressive contact.The design of the valve seat, the valve plate in the process of close contact with the valve seat to ensure good sealing performance at the same time reduce unnecessary torque, thereby prolonging the service life of the valve seat.

3.Torque reduction to achieve the lightweight and miniaturization of the drive device.

4.Unique stem sealing ring to prevent fluid leakage.

5.Different materials of the valve seat to adapt to different conditions, with good corrosion and sealing performance.

1.OEM is available

2.Full set of valve moulds with different weight to satisfy with customer’s different requirement.

3.Precision casting and sand casting

4.Our own foundry to guarantee fast delivery and quality

5.The price of big size valve is very advantageous

6.Certificates available: WRAS/ DWVM/ WARC/ ISO/CE/NSF /KS/TS/BV/SGS/ TUV …

7.Professional QC department to control product quality, and each valve will be arranged hydro test twice before shipment

8.Mill test certificate and inspection report will be provided for each shipment