China OEM DIN3202 F6 Ductile Iron Ball Check Valve Flange End for Water Pump

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of China Check Valve and Ball Check Valves. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us.

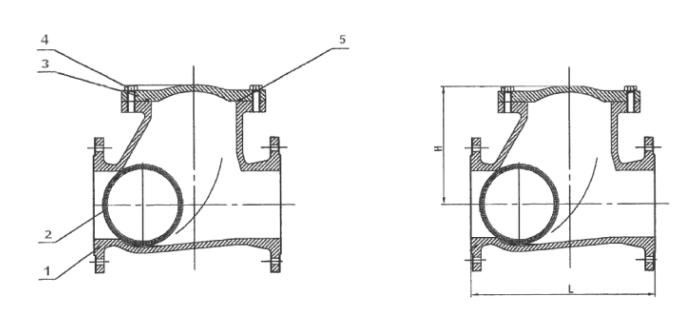

Components

| No. | Part name | Material | Surface treatment |

| 1 | Body | Ductile iron | Epoxy coating |

| 2 | Ball | Alluminium+ NBR(2"-6") Carbon steel+ NBR(8-24") | NBR |

| 3 | Cover | Ductile iron | Epoxy coating |

| 4 | Bolt | S.Steel | |

| 5 | Gasket | NBR |

1.OEM & customization capability

2.Our own foundry(Precision casting/Sand castings) to guarantee fast delivery and quality

3.MTC and inspection report will be provided for each shipment

4.Rich operating experience for project orders

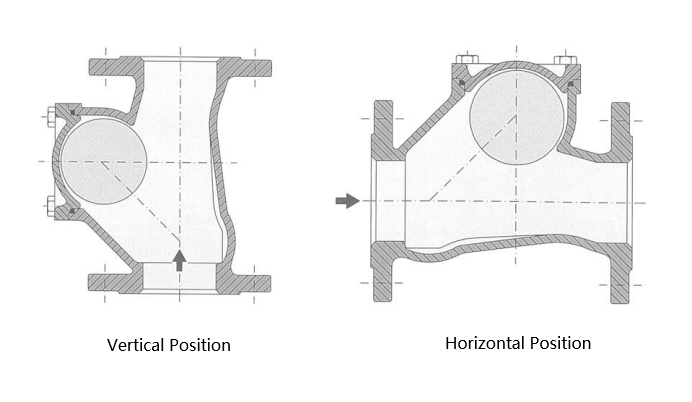

Ball Check Valve is a simple and reliable valve with the only moving part to block the reverse flow, is a spherical ball. The full-ported valve seat is uniquely designed allowing the ball to seat leak-tight without getting wedge into the valve seat. For vacuum or anti-flooding valve application, a "floating" rather than "sinking" ball is used. Due to its simple flow efficient and virtually maintenance-free design the valve is commonly specified and used in submersible wastewater lift stations

The standard ball is designed with a NBR rubber lined metal core, and the rubber hardness is optimized to prevent the ball from getting stuck in the seat. Balls of polyurethane are suitable for abrasive media and when different balls weights are needed to prevent noise and water hammer. A full and smooth bore ensures full flow with low pressure loss and eliminates the risk of deposits at the bottom that could prevent tight closure.