GDLF Series vertical multistage centrifugal pump

1.This series of pumps for the vertical, multi-level,segment-type structure,compact structure,small footprint.

2.Shaft seal is a mechanical seal and can be chosen demolition, less leakage,stable and reliable operation,and easy maintenance.

3.The pump body adopts the pipeline type structure, its inlet and outlet diameter are the same and are on the same straight line. It can be installed at any position of the pipeline like a valve. It is convenient, fast and stable.

4.To facilitate the installation can choose the upper outlet type, the direction between the import and export can be adjusted to the user's requirements 0°,90°,180°,270°.

5.If you need shock absorption, reduce noise, you can use the installation of connecting plate and vibration isolation pad or vibration isolator installation.

6.Unique installation structure greatly reduces the floor area of the pump, can save more than 40% of infrastructure investment.

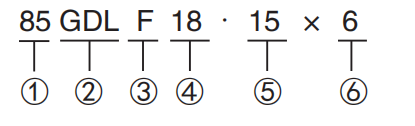

1.Pump caliber(mm)

2.Vertical multi-stage centrifugal pump

3.The material of pump

4.Design point flow rate( m³/h)

5.Single stage lift(m)

6.Pump series

|

Description |

CDL ( F ) 1 |

CDL ( F ) 2 |

CDL ( F ) 4 |

CDL ( F ) 8 |

CDL ( F ) 16 |

CDL ( F ) 32 |

CDL ( F ) 42 |

CDL ( F ) 65 |

CDL ( F ) 120 |

CDL ( F ) 150 |

CDL ( F ) 200 |

|

Rated Flow ( m³/h ) |

1 |

2 |

4 |

8 |

16 |

32 |

42 |

65 |

120 |

150 |

200 |

|

Rated Flow ( L/s ) |

0.28 |

0.56 |

1.1 |

2.2 |

4.4 |

8.9 |

11.7 |

18 |

33 |

41.6 |

55.6 |

|

Flow Range ( m³/h ) |

0.4-2 |

1-3.5 |

1.5-8 |

5-12 |

8-22 |

16-40 |

25-55 |

30-80 |

60-150 |

80-180 |

100-240 |

|

Max. Pressure ( bar ) |

21 |

23 |

21 |

22 |

26 |

30 |

22 |

17 |

16 |

16 |

16 |

|

Motor Power ( kw ) |

0.37-2.2 |

0.37-4 |

0.75-7.5 |

2.2-15 |

1.5-30 |

3.0-45 |

4.0-45 |

5.5-45 |

11-75 |

11-75 |

18.5-110 |

|

T Range (℃) |

-15 ~ +120 |

||||||||||

|

Max. Efficuency ( % ) |

46 |

57 |

62 |

66 |

73 |

75 |

76 |

77 |

74 |

73 |

79 |

|

Type |

CDL/CDLF |

||||||||||

|

DIN Flange |

DN25 |

DN32 |

DN40 |

DN50 |

DN65 |

DN80 |

DN100 |

DN100 |

DN125 |

DN125 |

DN150 |

|

Over Flange |

G1 |

G1¼ |

G1 ½ |

- |

- |

- |

- |

- |

- |

- |

- |

|

Cutting Ferrule Joint |

DN32 |

DN32 |

DN50 |

DN50 |

DN50 |

- |

- |

- |

- |

- |

- |

|

Pipe Thread |

ZG1¼ |

ZG1¼ |

ZG2 |

ZG2 |

- |

- |

- |

- |

- |

- |

- |

|

Remark |

Parameter table above is only a part of whole. For more, please contact us directly. |

||||||||||

1.OEM & customization capability

2.Our own foundry(Precision casting/Sand castings) to guarantee fast delivery and quality

3.MTC and Inspection report will be provided for each shipment

4.Rich operating experience for project orders