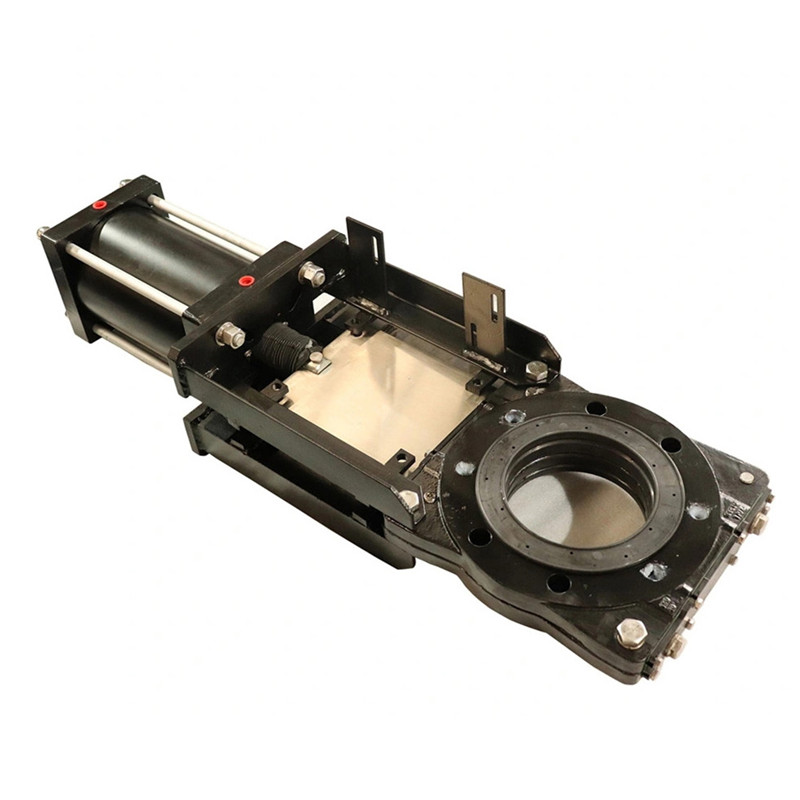

Unidirectional/Through conduit/Slurry knife gate valve

Uni-directional wafer valve designed for general industrial service applications. The design of the body and seat assures non-clogging shut off on suspended solids in industries such as: Pulp and Paper, Wastewater treatment plant, Power plants, Chemical plants, Bulk handling.

Customized design on request: Deflection cone, Flush ports, Spring return pneumatic cylinder, Fail safe system.

For the bonneted knife gate valve, It can ensure a tight seal with the atmosphere and reduce packing maintenance.

For the knife gate valve conforming to MSS-SP-81,has the advantages of Compact design, Replacement seat, High quality knife finish for optimum sealing, Handwheel and pneumatic type interchange.

Bidirectional design which is ideal for installations handling large solids, very viscous fluids, sludge and highly concentrated slurry(mining, paper industry, cement industry, etc.).

The main characteristic of the blade is that it passes through the entire length of the body.

A round outlet is machined in the middle of each blade. This outlet, while falling with identical outlet on the valve body, allows for maximum direct flow of the medium. Thus, while being in open position, the valve essentially becomes part of the piping (leading to dead zones elimination).

Characteristics:

Bidirectional; Knife goes through the seal area; Two-piece body; Circular, total passage: enables a high flow capacity with low load loss; sided seal-seal and support ring on both sides.

Slurry knife gate valve built with a cast body and features a heay-duty stainless steel knife. Removable seats on both sides of the gate provide a bi-directional bubble tight seal, with no metal parts in contact with the slurry: Heavy-duty cast body; Heavy-duty yoke frame; External epoxy coated; Lubrication ports; Flushing ports; Open/closed lockout brackets standard.

Customized design on request: Safety covers on yoke frame; Spring return pneumatic cylinder; Fail safe system.