Factors affecting the selection of check valve type Due to the variety of check valves, it is inevitable to involve the selection of check valves in the pipeline design of petrochemical plants. Whether the selection of check valve type is reasonable not only affects the investment of engineering construction and the normal production of equipment, but also affects the safety of pipeline system and equipment. Therefore, the selection of check valve is very important. The main factors affecting the selection of check valve type are as follows :

(1) First of all, we should understand the purpose of setting check valve to meet the process requirements.

When the process has special requirements for the structure of the check valve, it should generally be indicated in the PID ( process pipeline instrument flow chart ). For example, the reciprocating compressor outlet pipeline, the process will require the use of non-impact check valves, the purpose is to avoid frequent fluctuations in the outlet pressure of the reciprocating compressor, resulting in frequent opening and impact of the check valve disc, resulting in check valve damage. For centrifugal pumps with a pressure difference between the outlet and the inlet greater than 4.0Mpa, the process generally requires different types of double check valves to be installed on the pump outlet pipe.

This is due to the large pressure difference between the pump outlet and the inlet, and the leakage of the check valve is large when the pump suddenly stops running. In order to reduce the leakage of the check valve and reduce the probability of damage and failure of the check valve, two different types of check valves are used.

(2) Should meet the requirements of pressure drop.

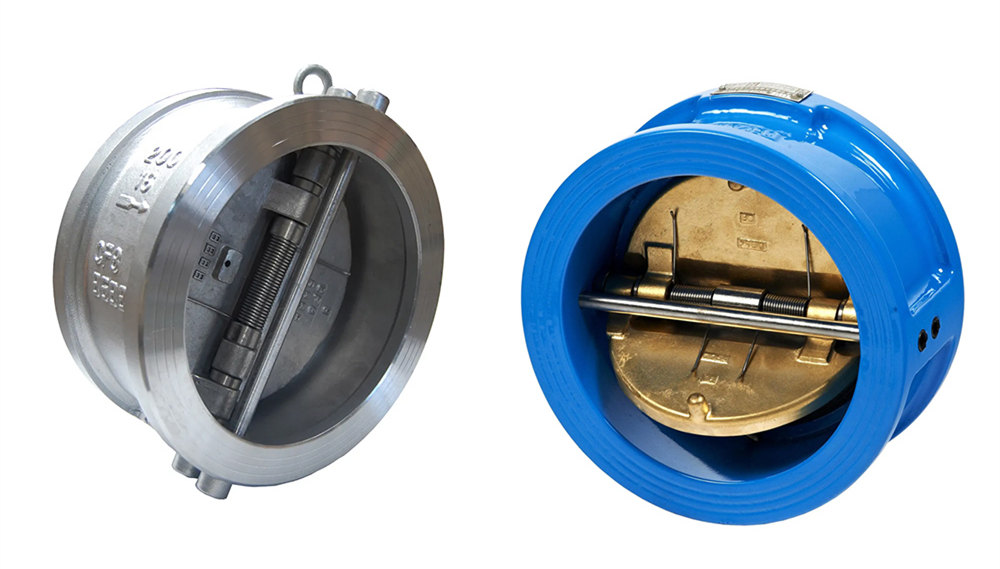

Some pipelines are particularly strict with the pressure drop requirements. The check valves on these pipelines will use low pressure drop check valves, commonly used double-plate check valves, etc. If necessary, simulation calculations are also needed to determine whether the pressure drop meets the design requirements.

(3) Operating pressure requirements.

For the large diameter check valve with very low operating pressure, if the standard pressure level swing check valve or lift check valve is selected, the valve disc may not be opened under normal operating conditions due to the heavy valve disc. For the high pressure check valve with high operating pressure, the check valve with pressure sealing valve cover can be selected.

(4) The influence of valve size.

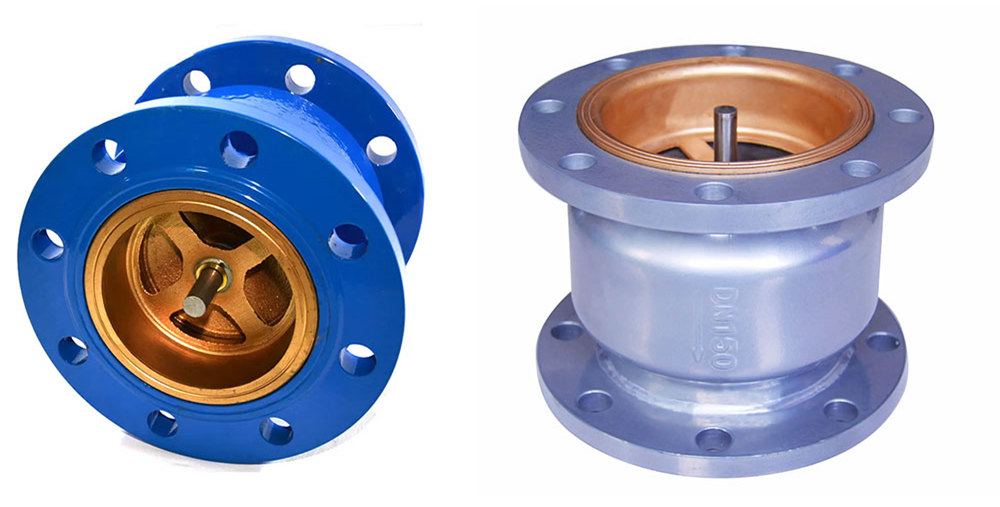

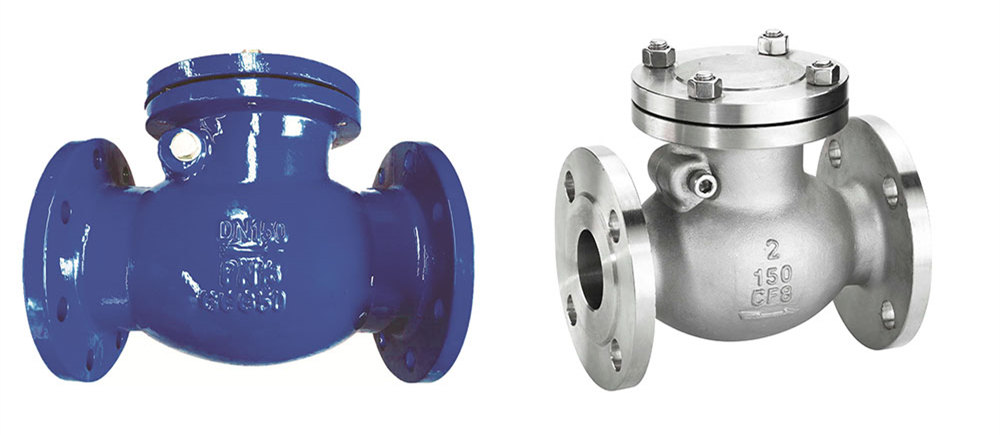

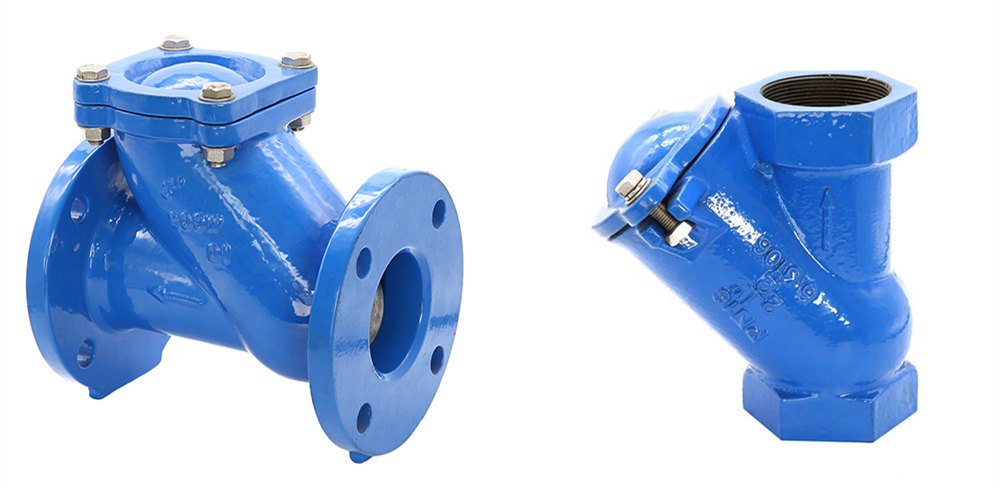

General nominal diameter is less than DN50 check valve commonly used lift check valve ; when the nominal diameter is greater than or equal to DN50 and less than DN400, the swing check valve can be selected. When the nominal diameter is greater than DN400 and less than DN600, the disc check valve can be selected. When the nominal diameter is greater than DN50 and less than DN1200, the double-plate check valve can be selected.

(5) The influence of installation direction

Lift check valve without spring should be installed on the horizontal pipeline ; the swing check valve and the swash plate check valve are generally installed on the horizontal pipeline;The plate check valve,The axial flow check valve can be installed horizontally or vertically.

(6) The influence of installation space

For the larger diameter check valve, when the installation space is small, the double plate check valve can be selected.

(7) Economic impact

When a variety of check valves can meet the requirements, the check valve with simple structure and low price should be preferred. In petrochemical plants, the most used are lift check valves and swing check valves.

The selection of check valve can not only consider the influence of single factor, but also the result of comprehensive consideration of many factors. The applicable occasions of several common check valves are shown in table.

Post time: Mar-17-2023