Heat transfer oil is a kind of special oil with good thermal stability used for indirect heat transfer. Heat conduction oil can not only meet the heating and cooling process requirements of different temperatures in a wider range of temperatures, but also realize the process requirements of high temperature heating and low temperature cooling with the same heat conduction oil in the same system, which can reduce the complexity of the system and operation. Therefore, heat conduction oil heating system is widely used in chemical fiber, material and other industries.

Characteristics of heat conduction oil system:

1.Under the condition of almost atmospheric pressure, can obtain very high operating temperature - that is, can greatly reduce the operating pressure and safety requirements of high temperature heating system, improve the reliability of the system and equipment;

2.The heat-conducting oil heating system omits the water treatment system and equipment, which improves the thermal efficiency of the system and reduces the maintenance workload of equipment and pipelines -- that is,the initial investment and operating costs of the heating system can be reduced.

Potential risks of thermal oil system performance:

1.Due to the local overheating of the heating system during the use of the heat-conducting oil, thermal cracking reaction is prone to occur, resulting in volatile and low flash point oligomers. Polymerization between oligomers produces insoluble and insoluble polymers, which not only hinders the flow of oil products and reduces the same heat conduction efficiency, but also causes the possibility of local overheating deformation and burst of the pipeline.

2.Heat transfer oil and dissolved air and heat carrier system filling is the oxidation reaction of residual air under heating condition, and the formation of organic acid and colloid adheres to the oil pipeline, which not only affects the service life of heat transfer medium and blocks the pipeline, but also easily causes acid corrosion of the pipeline and increases the risk of system operation leakage.

The accidents of heat transfer oil heating system include: fire of thermal insulation layer, fire of expansion tank exhaust and thermal insulation layer, fire of heat transfer oil system operation area, fire and explosion of heat transfer oil storage tank, fire and explosion of heat transfer oil heat exchanger or reactor (kettle), furnace explosion, etc. It can be seen that many common thermal oil heating system accidents are more or less related to leakage.

Valve requirements for standard technical and design specifications in hot oil systems include: an exhaust valve at the highest point and a blowdown valve at the lowest point. The pipe line of the hot oil system must be connected with flanges except for device interfaces, instrument interfaces or valves. All other interfaces are welded. The flange should be set groove surface, and the nominal pressure should not be less than 1.6MPa. For heat conduction oil with temperature higher than 300 degrees, the nominal pressure of the flange should not be less than 2.5MPa. Flanges should be butt welded instead of flat welded flanges. The flange gasket of hot oil system is not allowed to use asbestos rubber plate, metal winding pad or expanded graphite composite pad should be used. The hot oil system should be provided with a safety valve, and the safety valve should be bellows sealed safety valve.

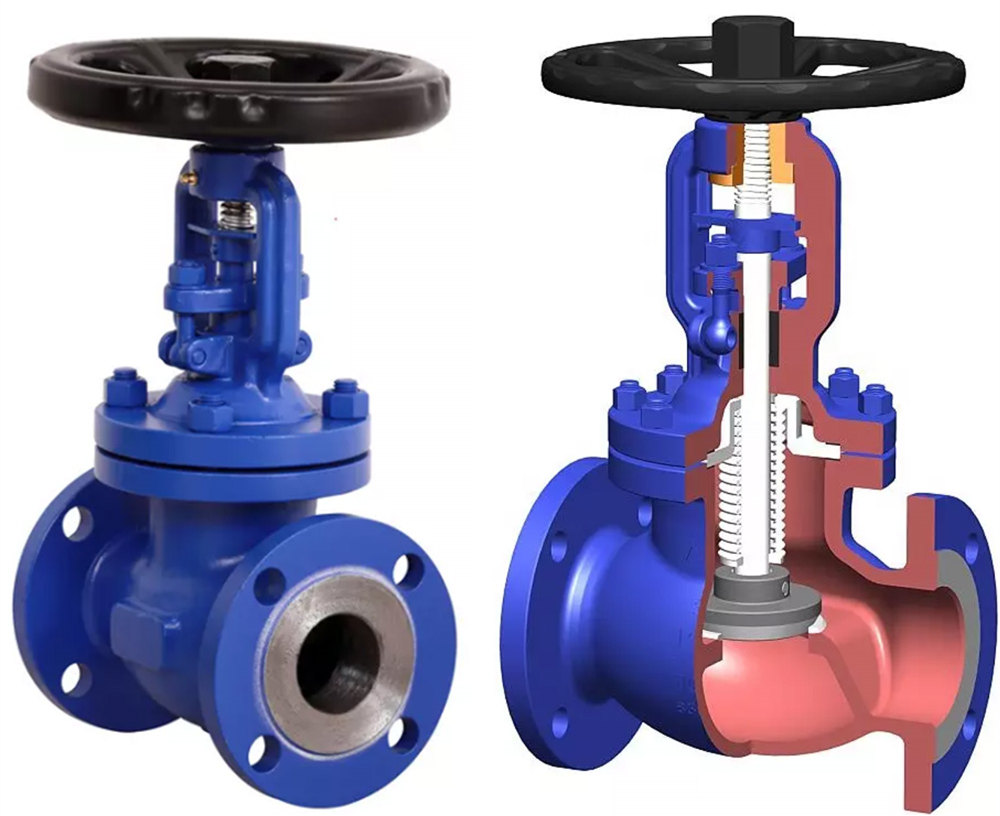

The valve material of hot oil system shall not be cast iron or non-ferrous metal. Considering its low pressure, high temperature and permeability is particularly strong, according to the standard technical design specifications, the hot oil pipeline cut off valve should use bellows seal cut-off valve, regulating valve should use bellows seal sleeve regulating valve, safety valve using full open bellows seal safety valve.

Due to the characteristics of oxidation stability of heat conduction oil, the leakage of hot oil valve will not only cause the combustion of insulation layer or the combustion and explosion of equipment, but also cause the oxidation reaction of heat conduction oil and dissolved air in the case of heat, generating organic acid corrosion valve internals. So the hot oil valve should not only do no internal leakage, but also do no external leakage.

General packing globe valve packing by graphite processing molding, if the purity of graphite is not enough, its oil resistance will become very poor, when the heat conduction oil into the graphite packing, some impurities in the graphite is easy to be dissolved by heat conduction oil, resulting in graphite powder, can not make the graphite packing to achieve sealing effect, this is the main cause of packing valve often leakage. The bellows seal prevents direct contact between hot oil and graphite, which solves the problem of hot oil leaking from the stem when the graphite packing is dissolved.

Because the permeability of heat conduction oil is very strong (about 50 times that of steam), if the filler seal is selected, it is very easy to leak out, leading to waste of hot oil, dirty equipment and ground, and the bellows structure can completely realize zero leakage, and no wearing parts.

Due to the potential danger of oxidation stability of heat conduction oil, the internal parts of the valve are made of stainless steel, which can withstand 425℃ high temperature, corrosion resistance, and the switch is particularly easy.

From the overall life point of view, the service life of the general bellows sealing valve is better than other valves. The heat transfer oil has high viscosity and large flow resistance in cold state. The valve core adopts fast opening type, which can improve the flow rate and overcome the flow resistance well when starting. Therefore, in order to ensure the stability of production, but also in order to reduce the actual operating cost, the heat transfer oil system should choose the quick opening valve core of the bellows seal stop valve, can not choose the packing seal stop valve or general valve.

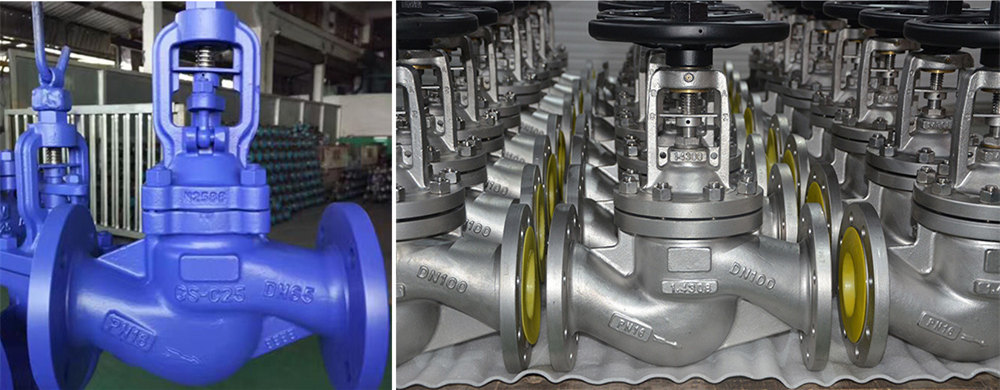

Bellows sealing globe valve produced by BESTOP is very suitable for cutting off the pipeline transportation of hot oil system.

Post time: Jan-29-2023