Triple eccentric butterfly valve

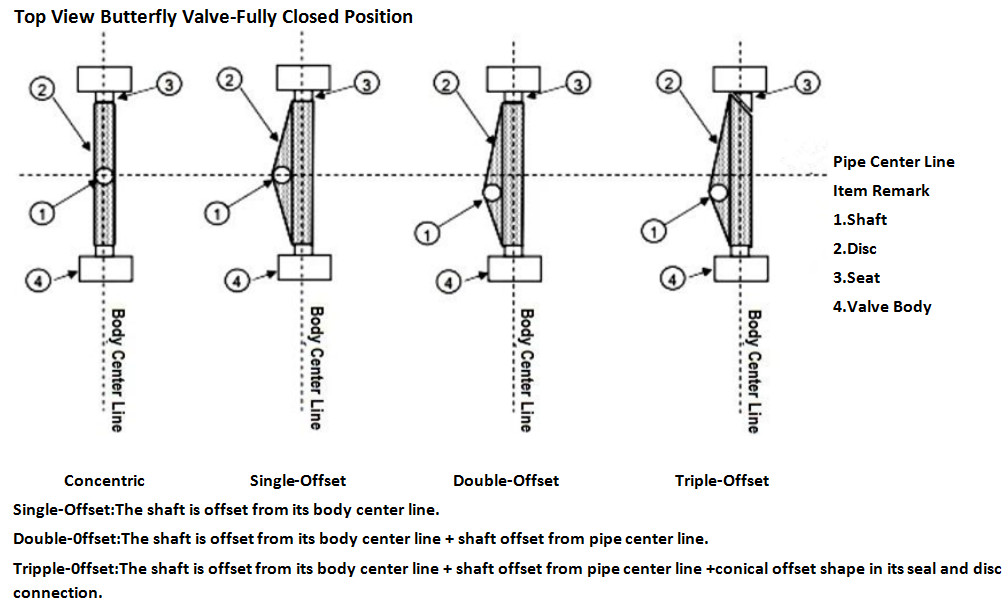

The first offset is that the valve shaft is behind the disc shaft so that the seal can completely close the entire valve seat.

The second offset is that the center line of the valve shaft is offset from the pipe and valve center line to avoid interference from valve opening and closing.

The third offset is that the seat cone axis deviates from the center line of the valve shaft, which eliminates friction during closing and opening and achieves a uniform compression seal around the entire seat.

Triple offset butterfly valves offer several advantages compared to other valves typically used in most upstream applications:

1.For the harsh conditions of critical process applications, steam isolation and temperature extremes, triple offset butterfly valves provide performance reliability and quality.

2.The bi-directional zero leakage closure with a metal seat, even after extensive cycling, provides sealing integrity formerly associated only with soft-seated valves.

3.Low torque from quarter-turn action permits smaller actuators and lower cost.

4.The triple offset butterfly valve is inherently fire safe with a non-rubbing rotation and fire-tested designs per API 607.

5.Its compact design makes the installation easier since the valves are lighter and require less pipe bracing.

6.Triple offset butterfly valves can provide reductions in weight and space and substantial cost savings.

The triple offset butterfly valves are used where a metal seat is required, tight shutoff and quarter turn actuation is desired.Following are some industries where triple offset butterfly valves are used:Oil & Gas,Energy & Power,Water and Wastewater Treatment,Chemicals,Food & Beverages,Pharmaceutical & Healthcare,Metals and Mining,Building & Construction,Paper and Pulp...