ZD(ZDG,ZDF,ZMD) Self-balancing Multistage Pump

This series pump is horizontal single suction multistage sectional centrifugal pump,owned 6 national patents, and with high efficiency, wide performance,steady and safety operation, low noise, long operation, easy installation.

It can deliver the medium with solid particles, besides, it can be changed the pump materials, seal type , add cooling system then can deliver the hot water, oils corrosive liquid, and abrasive medium. The material of pump:HT200,QT600,JM3,304,304L,316L, Inconel and so on.

We have passed ISO9001:2000 quality system certification, strictly control the pump design, production and service, totally make sure the pump quality.

Model Significance

ZD(ZDG,ZDF,ZDY,ZMD)46-30×4

ZD:Self-balancing multi-stage centrifugal pumps

ZDG:Self-balancing multi-stage boiler feed pumps

ZDF:Self-balancing multi-stage anti-corrosive pumps

ZMD:Self-balancing multi-stage anti-corrosive & erosive pumps

46:Rated Flow is 46 m³/h

30:Rated head for 1 stage is 30m

4:Number of stage for Pump is 4 stages

-

-

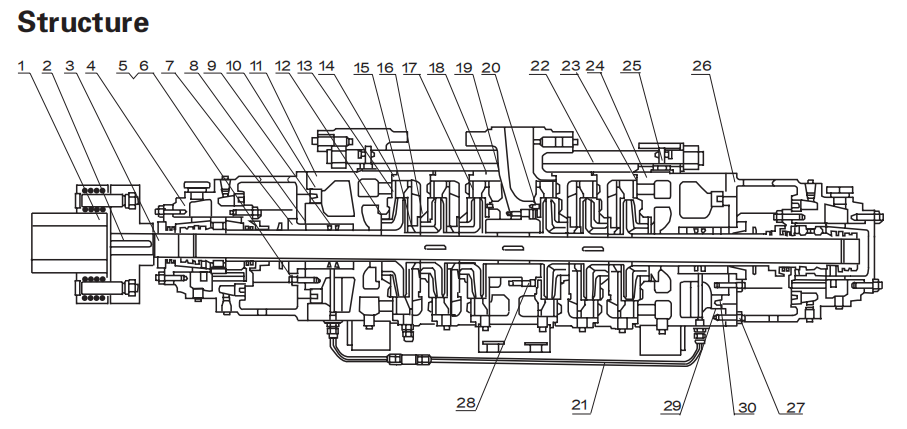

No.

Part Name

No.

Part Name

No.

Part Name

No.

Part Name

1

Coupling Assembly

9

Lantern Ring

17

Discharge Diffuser

25

Air Release Valve

2

Key

10

Cooling Chamber Cover

18

Discharge Casing

26

Bearing Housing B Assembly

3

Rotating Assembly

11

Suction Casing

19

Orifice Sleeve

27

Stud&Nut

4

Bearing Housing Assembly

12

Wear Ring

20

Dowel Pin

28

Hexagon Socket Head Cap Screw

5

Stud

13

Diffuser

21

Seal Flush Pipe Assembly

29

O-ring

6

Nut

14

Stage Casing

22

Tie Bolt

30

O-ring

7

Packing Gland

15

Inter-stage Bushing

23

Gasket

8

Packing

16

Wear Ring

24

Scend Suction Casing

Performance data for ZD,ZDG,ZDF,ZDY,ZMD

Type

Series

Speed ( r/min )

Flow

( m³/h )

Head ( h/m )

( NPSH )

r/m

Motor Power ( kw )

Impeller Dia ( mm )

6-25×3

3

2950

6.3

75

2

4

Φ139

6-25×4

4

2950

6.3

100

2

8

Φ139

6-25×5

5

2950

6.3

125

2

8

Φ139

6-25×6

6

2950

6.3

150

2

11

Φ139

6-25×7

7

2950

6.3

175

2

11

Φ139

6-25×8

8

2950

6.3

200

2

15

Φ139

6-25×9

9

2950

6.3

225

2

15

Φ139

6-50×3

3

2950

6.3

150

3

11

Φ198

6-50×4

4

2950

6.3

200

3

18.5

Φ198

6-50×5

5

2950

6.3

250

3

22

Φ198

6-50×6

6

2950

6.3

300

3

30

Φ198

6-50×7

7

2950

6.3

350

3

30

Φ198

6-50×8

8

2950

6.3

400

3

37

Φ198

6-50×9

9

2950

6.3

450

3

37

Φ198

6-80×3

3

2950

6.3

240

3

18.5

Φ235

6-80×4

4

2950

6.3

320

3

22

Φ235

6-80×5

5

2950

6.3

400

3

30

Φ235

6-80×6

6

2950

6.3

480

3

37

Φ235

6-80×7

7

2950

6.3

560

3

45

Φ235

6-80×8

8

2950

6.3

640

3

45

Φ235

6-80×9

9

2950

6.3

720

3

55

Φ235

12-25×3

3

2950

12.5

75

2

7.5

Φ146

12-25×4

4

2950

12.5

100

2

11

Φ146

12-25×5

5

2950

12.5

125

2

11

Φ146

12-25×6

6

2950

12.5

150

2

15

Φ146

12-25×7

7

2950

12.5

175

2

15

Φ146

12-25×8

8

2950

12.5

200

2

18.5

Φ146

12-25×9

9

2950

12.5

225

2

18.5

Φ146

12-50×3

3

2950

12.5

150

2

15

Φ198

12-50×4

4

2950

12.5

200

2

22

Φ198

12-50×5

5

2950

12.5

250

2

30

Φ198

12-50×6

6

2950

12.5

300

2

30

Φ198

Remark

Parameter table above is only a part of whole. For more, please contact us directly.

-

1.OEM & customization capability

2.Our own foundry(Precision casting/Sand castings) to guarantee fast delivery and quality

3.MTC and Inspection report will be provided for each shipment

4.Rich operating experience for project orders